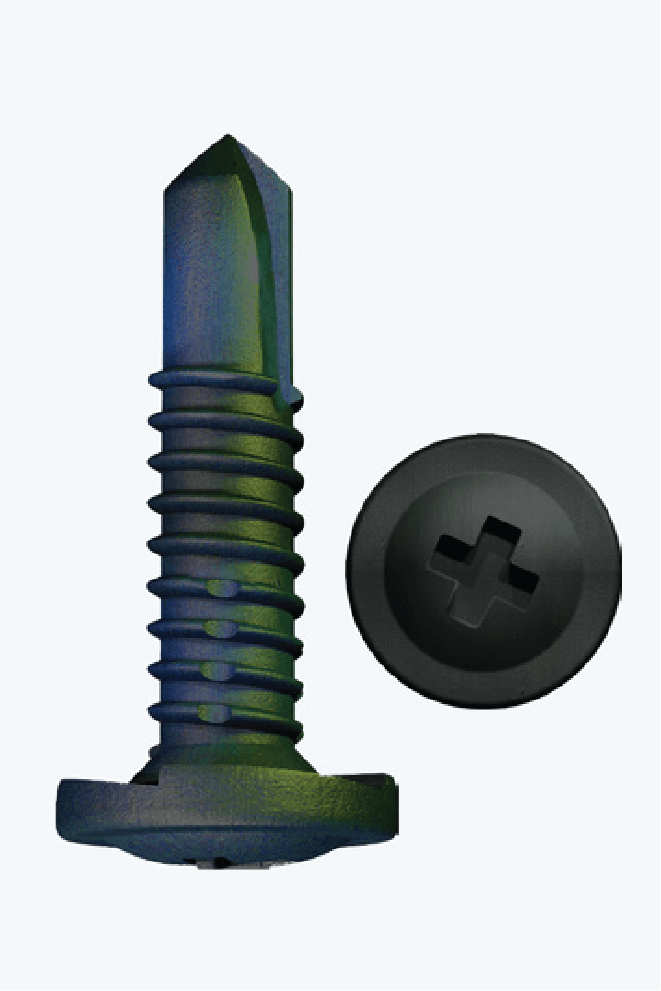

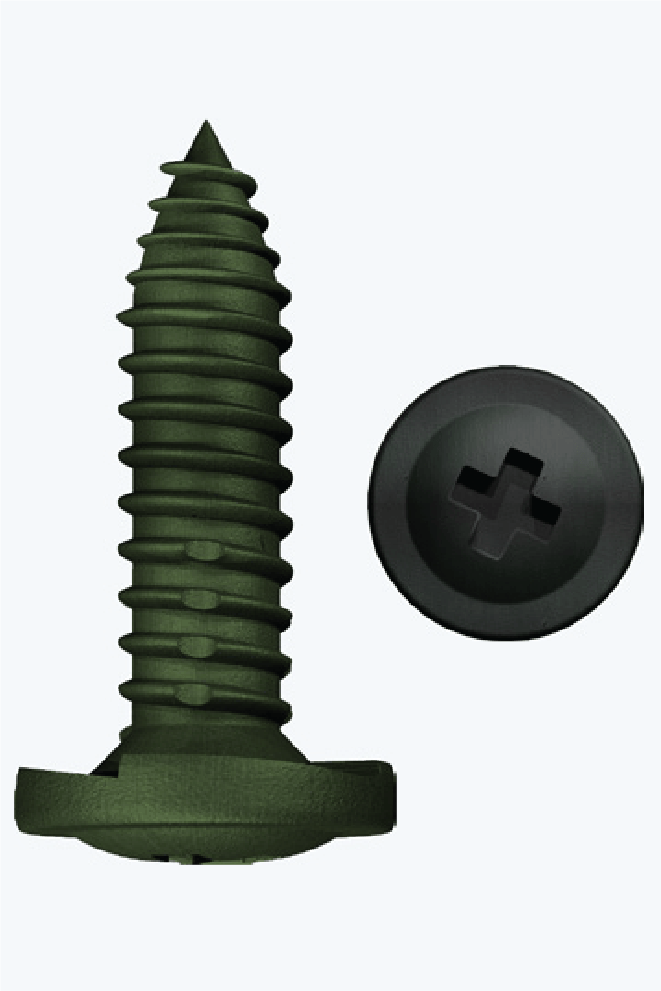

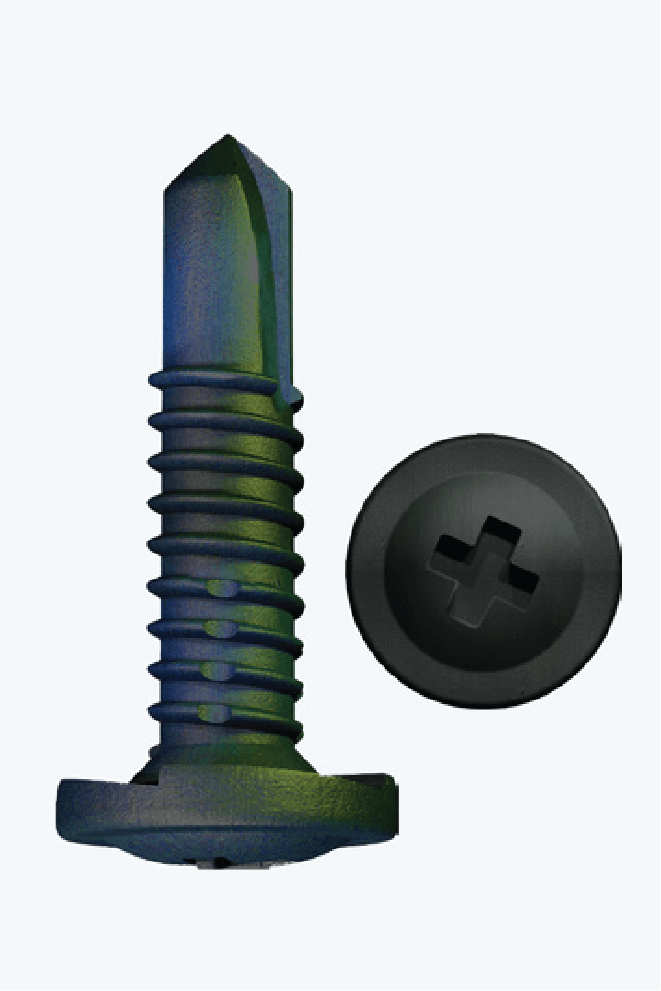

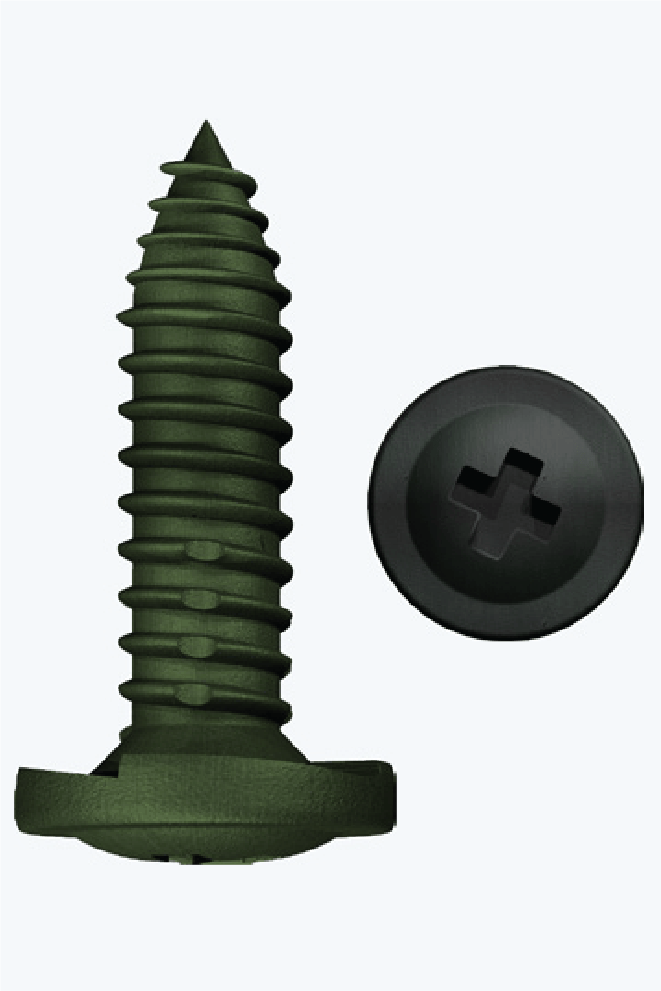

Main Application

• Pre-fabrication of steel frame walls and trusses

• Drill Point: Designed for pre-punched as well as non-punched, BMT 0.95 to 1.55 mm steel

• Pre-fabrication of steel frame walls and trusses

• Drill Point: Designed for pre-punched as well as non-punched, BMT 0.95 to 1.55 mm steel

• Self tapping Sharp Point aligns pre-punched holes during frame assembly for a high quality, accurate finish.

• Self tapping Drill Point is designed for easy penetration into heavier gauge steel for quick and easy assembly.

• X-Drive® recess delivers increased stability and higher torque making it significantly easier to drive, reducing worker fatigue and

increasing productivity.

• X-Drive® incorporates a larger surface area of engagement, reducing stress on driver bits resulting in fewer breakages.

• Low profile flat head sits perfectly flush with dimple providing a smooth, flat finishing surface for easy and accurate installation of

cladding and lining.

• Underhead serrations slow the head down when rotating, reducing the opportunity for strip out and providing resistance to back out,

lessening the chance for vibrational loosening during transportation.

• Thin E-Coat plating (optional) enables better driver engagement and smoother driving as the coating does not strip and clog threads.

Additionally, E-Coat offers a high level of corrosion resistance and durability to the X-Drive® screw.

• Compatible with Superdrive® collated screw system for increased speed.

• Quality assured, tested and engineered for strength and capability (FRAMECAD® Screw Connection Design Capacity Report available on

request).